Professor in Residence, Department of Architecture, GSD, Harvard University, Cambridge MA, USA

Architecture is the stage on which all human stories are lived out.

Where once the stage was constructed by everyone, the stage today is almost exclusively constructed by professionals, virtually all of whom specialize in one trade or another. The growing, economically motivated separation between professional builders on the one hand, and users of the built environment on the other, is socially and environmentally destabilizing.

“Ordinary” human beings are losing their ability to participate in the construction of society’s largest undertaking – the built environment. That loss is leading to a slow erosion of human skill, social and physical engagement, and individuality.

Since the beginning of the industrial revolution, the construction and operation of the built environment has consumed natural resources at a rate that has exceeded global population growth. In too many cases these resources have been wasted only to create urban ugliness.

Technological advancement, standardized industrial processes, and our own unexamined belief systems and habits – especially those that have been promoted as saving time, reducing costs, or offering more comfort and amenities in our built environment – have delivered uneven benefits.

Except in a handful of countries, construction projects across the world do not move any quicker than they used to fifty years ago. Homes and commercial real estate are becoming more expensive and are increasingly out of reach for the majority. Cities around the world are shedding their identities; many modern buildings in Tel Aviv are practically indistinguishable from those in Mumbai. The loss of aesthetic diversity is its own unique form of ugliness – as if all human stories are the same.

Why have the purported gains from technological advancement not resulted in housing that is more broadly accessible? What should we do about the conflict between our desire to improve living conditions for all of humanity versus the unsustainable trends in resource consumption? And what of the largest losses of all – our skills, our capacity to think, and our sense of purpose and belonging?

A PRINCIPLED APPROACH

The answers to these questions may lie in re-examining those habits of mind and body that humanity has adopted during the long process of industrialization. Foremost among these are the notions of time and its scarcity. If time is perceived to be scarce, then it follows that a rational professional (an architect!) would prefer to specify pre-designed, standardized materials and components and outsource to experts those tasks she believes she is not qualified to handle.

That preference, once it becomes a reflexive habit, has pernicious effects on the choice of form and materials. These effects are a consequence of the growing and unquestioned disconnect between what might have been possible with a bit more thought versus what ends up happening when design decisions are effectively outsourced to someone with a standardized product or preferred solution.

The point is simple: we think we do not have time, so we do not take the time to think. That mindset has avoidable consequences. This article is about how to avoid that mindset and its consequences.

Just as athletes seeking to develop strength and endurance spend countless hours in practice and all their energy in exercise, so also should we, seeking more engaged and purposeful lives, look to spend (not save!) more time in deliberately creating the built environment of the future.

Our time is not an “expense” to be minimized. Rather, it is a wasting resource that we should be eager to employ. It is the misguided disuse of our time (and therefore our intelligence) that leads to wasteful overconsumption of finite natural resources and a lower quality of life. The idea is to imaginatively and purposefully use our time to create an abundance that can benefit all.

The strategies discussed below can help thoughtful design professionals achieve multiple objectives at once – reduce a building’s environmental footprint, extend finite resources, house more people, develop human capital by teaching building trades and skills, and support local economies.

The most important principle guiding any effort to alter mindsets and practices surrounding urban materiality is this: the emergent built environment must facilitate better lives for all of humanity.

1. Material Is Best Treated as a Local Matter

If we only ever buy berries at the supermarket, it is not easy to identify edible berries in the wild.

Once we get used to sourcing materials and components from catalogues and industrial-scale suppliers, local materials fade into and look like part of the landscape.

Yet, throughout history humans have built great structures by using stone, clay, wood, and other materials they could find at or near the building site. Think of how often fieldstone at a site is dug out and discarded only to make way for purchased building materials with similar properties!

An important advantage of using local materials is that this approach usually improves employment prospects for local craftsmen who are more familiar with those very materials. And, of course, it saves on transportation costs and emissions too.

Samskara: Made in India (New Delhi, 2017) was an exhibition of high-end, hand-crafted contemporary products. Granite from a local quarry was used to emphasize local stone-cutters’ craftsmanship – making thick white slabs look like delicate flying ribbons. The ribbons served both as the exhibition hall floor and as the stage for the products. Between the ribbons, 5.08 cm [2 in.] to 7.62 cm [3 in.] streaks of crushed darker granite provided visual relief. Their more important (and unnoticed) role was to absorb the inevitable dimensional variances between working drawings and the actual site.

Photo by © Vimal Bhojraj.

2. Known Materials and Technologies Have Uses We Have Yet to Discover. Experiment Boldly

If you see the object on the left/right simply as a clay pot then all you will see is that you can use it to fetch and store water, or cook food in. If, on the other hand, you can see it as an object with a convex surface made of a sturdy material, then you can conceive other uses for it. For example, you could use it as lost formwork for a coffered ceiling. By removing concrete from that portion of the slab experiencing tension, we make the slab stronger, lighter, and cheaper to produce.

Baked in-situ mud houses, which look a lot like traditional housing, are a novel way of recombining a known material (mud) and a known process (kiln firing). This novel approach does away with the need for cement (one way to reduce embodied energy, more on which later) since the bricks that make up the house are fused together during firing. Of course, the finished bricks require no (energy for) transportation since they are fired in place. Additionally, the house works as a kiln to bake other clay goods with marketable value (capturing heat energy that would go waste).

In summary, treat your project as a laboratory in which you encourage risk-taking to discover new ways to reduce the overuse of finite natural resources.

“Wall House” (Auroville, India, 1996) was a living laboratory that housed a decade of building technology experiments and prototyping. From 2.54 cm [1 in.] thick, pre-industrial achikal bricks, to vaulted brick and terracotta roofs, to coffered/filler concrete slabs, to innovative spaces and volumes, the Wall House has explored a range of building technologies using common materials and products (not typically used in building construction) in unexpected ways. The laboratory helped train a community of craftsmen who have since gone on to build commercially thriving construction ventures.

Photo by © Javier Callejas.

3. Old Can Be Gold

What one person thinks of as old-fashioned, another might consider a classic. Perceptions matter.

Around the world there are a plethora of time-tested, traditional building methods and styles (so-called “vernacular”) that offer important lessons and inexpensive alternatives to modern modes.

However, they do not attract the research and marketing funds that routinely flow to industrial technologies and products. The creators of the latter self-servingly (and incorrectly) presume that traditional systems are fossilized in time. Modern building codes therefore come to emphasize standardized industrial products and systems while extinguishing traditional methods that could offer equivalent benefits at a lower environmental cost.

Many traditional methods have been found to be cheaper, less wasteful, and better for local craftsmen and economies. By using them whenever practical, we can improve their odds of equal representation in regional and national building codes.

Earth construction is a common example of an age-old residential construction technology that is, unfortunately, no longer permissible under most building codes. Yet, the method is inexpensive and more than adequate (structurally and climatically) – especially when you consider the unmet needs of hundreds of millions of people.

Photo by © Andreas Deffner.

4. Design So Anyone Can Build

Not all construction activity requires highly skilled or experienced talent. Around the world there is an abundant pool of enthusiastic (if inexperienced) people able and eager to augment their income or contribute “sweat equity” for a chance to be able to afford a modest dwelling.

From hanging doors, to painting walls, to handling and organizing construction materials, there is a lot of work on a construction site that anyone can do. With modest changes to design details and the very choice of building technologies, we can expand the scope of such anyone-can-do-it activities and so encourage broader participation in the construction of our built environment.

Empirical observation and hard data confirm that this approach – encouraging broader participation in construction – reduces total construction costs, broadens affordability, and increases community engagement and skillsets that pay off handsomely via improved employment prospects.

“Creativity” (Auroville, 2003) is a 3,250 m2 [34,983 sq. ft.] urban eco-community focused on reducing costs by sharing spaces and resources and by enabling future residents to contribute labor. Construction details were simplified to allow even inexperienced individuals to participate and gain knowledge and expertise by doing. Clay excavated from an onsite wastewater treatment plant was used in cement-stabilized rammed earth walls which, because they require little more than brute force to construct, are a good way to conserve resources and invite the inexperienced to participate.

Photo by © Javier Callejas.

5. Build So Everyone Can Grow

Most people think that solid construction requires skilled and experienced personnel. Such talents being neither cheap nor plentiful, homes and other structures are becoming increasingly expensive. In response to any immediate shortage of experienced personnel, the construction industry – which is cyclical -- finds it uneconomical to invest in training people for skills that are unlikely to pay off by the end of the then prevailing construction cycle.

In the short run, it is cheaper to modify processes and technologies to allow more standardization and even mechanization. In the long run, standardization and mechanization reduce employment prospects within the construction industry and thus deplete hard-won skills and experience. The unintended effect is the economic impoverishment and demoralization of entire communities. The irony is that the process of “efficiently” constructing our built environment is inexorably dismantling the very society we are building it for.

When we invite broader (inexperienced) participation we are effectively recruiting for “attitude, not aptitude.” The approach yields a cohort of people who gain knowledge and experience which they otherwise would have no way to obtain. Along the way some may discover that they have a knack for the work and that it brings them joy, which leads to better economic prospects for themselves and a broader and deeper pool of construction skills in the community. One adjacent benefit of enabling the inexperienced to participate is that it develops project management skills which, of course, are broadly transferable.

By integrating “participatory construction” with local materials and craftsmanship one can reverse regional economic declines and gain a structural cost advantage over wasteful mechanized solutions.

“Volontariat Homes for Homeless Children” (Tuttipakkam, India, 2008) is a 500 m2 [5,382 sq. ft.] cluster of whimsical dwellings offering refuge to homeless children of all ages. The cluster of catenary domes made of sun-dried earth bricks with earth mortar were fired in situ to stabilize them into water resistant ceramic structures. Most of the budget went into labor with very little costs attributed to materials.

Photo by © Javier Callejas.

6. Waste Less Embodied Energy

Concrete is the second most widely used material on the planet with an annual consumption exceeding 10 km3 [2.4 cu. mi.]. High in embodied energy, it accounts for 5% of anthropogenic CO2.

Ferrocement is a low-embodied-energy variant of reinforced concrete. It consists of simple chicken-wire mesh sometimes augmented by a frame of ¼ in. [6.35 mm] steel rebar, with the whole assembly encased in cement plaster (as opposed to concrete which contains coarse aggregate). No more than an inch thick, it has superior strength-to-weight properties and conserves materials (cement, steel, aggregate) that are high in embodied energy. So, material conservation yields direct economic and environmental benefits.

“Full Fill Homes” (Modular, 57th National Association of Schools of Architecture Convention, Chennai, India, 2015) are a rapid and inexpensive housing solution with a far lower environmental impact than conventional methods. The design and the building technology (ferrocement) address three crucial and inter-related issues: affordable housing, decentralized economic opportunity, and environmental impact. Built from engineered, prefabricated ferrocement components, these modular homes can be assembled on site within a week (including foundation work) and are roughly 50% cheaper than conventionally produced housing with similar amenities. In addition to the basic structure, windows, doors, and other components are also made from ferrocement. Specialty pigments embedded in the cement slurry save on painting costs and give the smooth cement surfaces a waxed, waterproof finish. The folded and box-shaped components, designed to conserve and concentrate material where it is optimal (in webs and fins), double up as storage for clothes, books, kitchen utensils, and household effects. The approach saves on furniture and yields more living space.

Photo by © Javier Callejas.

Ferrocement is highly durable, offers better seismic force resistance (it bends where reinforced concrete would crack), and is exceptionally easy to maintain.

It is well-suited to offsite production where curing and other processes are easier to control. This, in turn, further improves strength-to-weight performance and ensures higher durability. When produced in the backyards of masons’ houses, ferrocement components offer a secondary source of income – more equitably distributed – with minimal capital outlay.

Another way to reduce waste is to use materials in their lowest possible energy state – which is to say one should minimize processing and transportation. Raw materials are much cheaper than, and often work just as well as, highly processed stuff. For example, level slabs of unpolished granite can be had for a fraction of the cost of polished granite tile. Granite slabs are stronger than tile and can serve as floor and sub-structure at the same time.

Similarly, a small diameter de-barked tree trunk is much cheaper than, and offers as good or better strength than, a square post sawed from a larger trunk.

All things being equal, the less we handle any material, the cheaper it will be for us and for the environment.

“Hut in Petite Ferme” (Auroville, 1990) was the first in a life-long quest for building systems that deliver a great deal with very little. Built from coconut thatch, thin casuarina trunks (debarked but unseasoned), coconut rope, and rough-hewn granite, it involved merely the dry assembly of lightly processed and unprocessed materials. The modesty of upfront capital investment did entail greater spending on periodic maintenance since elements like rope and thatch wear out more easily than more solid materials – a necessary and even welcome trade-off for people who have no access to credit but who, through work, can accumulate enough savings to manage small repairs over time.

Photo by © Andreas Deffner.

7. Trash Is Unimagined Treasure

Resource wastage in modern economies is a crisis that offers a substantial opportunity for re-thinking both how we design and how we use and maintain our buildings.

Old books and newspapers, glass bottles, and car tyres are examples of unconventional materials that can occasionally be repurposed as building materials or even formwork.

Another common example of resource wastage is dishwater or bathwater. If we think of it as “dirty” then we treat it as waste. If we think of it as a fluid that (with a little treatment) helps plants grow, then we end up with a functional grey water system that saves money in the long run.

“Unbound: The Library of Lost Books” (Barcelona, 2014) was a temporary pavilion of three “trees” with canopies made from obsolete city library books designated for destruction. Repurposing the books as foliage, the pavilion served as a place for reflection, rest, and a chance to re-think old constructs. The “trees” were later removed and re-assembled and found new life at a nearby public school where they remain to this day.

Photo by © Javier Callejas.

8. (Do The Math and You Will See That) Good Enough Is Perfect

Engineering firms are not usually invited early enough in the conceptual phase of a project to make a meaningful difference in material selection or quantities consumed. Nor are they asked to offer solutions that result in the least possible material usage to get the job done. Rather, they are usually asked to weigh in after critical design decisions are made and so they tend to focus on ensuring that a given design is safely engineered.

The process is recognized by architects and engineers alike as a short-sighted one in that it precludes critical thinking and instead defaults to codes and norms that can be quickly applied to a given situation to yield a safe, if over-designed, structure.

Rampant standardization nudges us to accept over-designed norms as the correct solution. But the norm has a factor of safety built in that is excessive or entirely unnecessary in many a specific context. In practice this means that some percentage of concrete slabs cast everyday are over-designed and thicker than they need to be. It means that everything from spatial dimensions to steel beams to floor tiles are, at least in some cases, larger than they reasonably need to be. The implications for material usage and environmental impact are…well, material.

Aside from the higher purchase cost, using more material than a situation warrants has multiple indirect consequences. Beams, columns, and foundations become costlier; transportation costs increase; and the amount of finishing (painting) required tends to be higher too.

“Sri Aurobindo World Centre for Human Unity” (Auroville, 2000) is a 300 m2 [3,229 sq. ft.] covered community space defined by eight inward-leaning concrete pillars supporting a circular concrete roof. The pitch and profile of the pillars (and other aspects of the design) were iterated several times to reduce structural spans and lighten the roof. The structure consumed only 75 m3 [2,648 cu. ft.] of concrete instead of the originally budgeted 125 m3 [4,414 cu. ft.].

Photo by © Javier Callejas.

9. Think to Learn with Your Hands

One troubling corollary of skill specialization in modern economies is that society is cleaving into two camps: people who work with their heads and people who work with their hands. This divergence is socially problematic, of course, but it also leaves everyone intellectually worse off.

For architects and architects-in-training there is no better way to learn – to navigate the gap between the elegance of theory and the rough reality of the world – than to work in the field and get one’s hands dirty. Climbing a long flight of stairs with the sun blazing overhead informs us about scale and place very differently than representing the same flight inside a .dwg file. Pour concrete and you understand the weight and workability of the material in a way that no numeric description can replicate. Sometimes we think and learn better with our hands (and on our feet!) and that sort of thinking takes time.

An even greater benefit of “thinking and learning with our hands” is that it allows us to establish a closer connection with the craftsmen and women who give physical form to our ideas. In turn, that connection has the power to make us aware of how even a small design decision or a minor sourcing decision helps or hurts a real person. This is engagement with a purpose, and it works.

Watch tower at Auroville’s Botanical Garden (2006) built by students from the AA School of Architecture using rope-tied round wood construction and coconut thatch. Other examples include:

• “Liquid Wall” backdrop constructed at a public space in Mexico City using discarded tetrapack containers refilled with sand or water;

• “Wall House” (2012) reconstructed in full scale at the Venice Architecture Biennale by students from the University of Queensland, Brisbane (Australia) and from the IUAV School of Architecture in Venice (Italy).

Photo by © Marta Sanvicente.

10. Avail of the Human Scale

We know scale confers benefits. But we also instinctively know that just because something is good, it does not mean that industrial-scale quantities of it must be better. The tyranny of monotony is an affront to the human scale which is about intimacy and uniqueness. It is craftsmanship – which is about producing a specific object for a specific person or situation – that more easily honors the human scale even as it reduces the waste that accompanies

over-designed standardized products.

The issue of scale applies not only to “what” is built but also to “how” we design and build.

Developer-driven construction projects are principally concerned with the most cost-effective (and therefore most profitable) production of marketable space. Qualitative design intangibles do not readily feature in these calculations.

Regardless of typology and project scale, then artisanal design practices – traditionally focused on the very intangibles that are hard to measure – are increasingly excluded from consideration.

But when projects are awarded to and delivered by large teams – complete with hierarchies and narrowly focused specialists – critical attributes like care and holistic attention may go missing.

Freed of administrative burdens and empowered to contribute all they can, small teams with members wearing, as it were, multiple hats may deliver much more at a lower total cost.

11. Develop What Is Plentiful and It Will Extend What Is Finite

Discussions of natural resources are pointedly silent on the one natural resource that is not only renewable but that grows and gets better over time – human resourcefulness.

Because our current economic system does not account for the full environmental and social costs associated with the extraction and use of natural resources (and the energy required for the same) it is easy to see why a machine powered by the energy equivalent of hundreds of humans will be cheaper to operate than hiring a human being - the energy contained in a barrel of oil approximates the work output of 2,200 humans.

The downside of the modern predilection for over-mechanization is that it diminishes our engagement with the built environment, reduces the potential for skill acquisition and intellectual and spiritual growth, and increases our propensity to accept the choices of “experts” and, indeed, accept an entire way of life that is alien to our needs and our natural condition.

This is a case where a bit of faith in human ingenuity – backed by only modest investments in time taken to think and experiment – could yield substantial savings and a lighter environmental footprint. Repeated a million times, these sorts of small decisions can greatly develop the human potential to create compounded economic, environmental, and social benefits.

12. Influence to amplify

Although it seems obvious, it still bears mentioning that policy and design choices made on an urban scale can have a disproportionate impact on the single site one is focused on. To maximize their environmental and economic impact, architects and urban designers could step outside the confines of their site and consider the bigger picture.

It helps to prioritize options that help neighbors and other stakeholders achieve their objectives. The approach opens the door to reciprocity and influence and can enable solutions (rainwater harvesting, wastewater treatment, shared gardens, reciprocal easements) that are difficult within a small project, but which may be undertaken co-operatively.

Cities are unique organisms that tend to promote and preclude specific development options. The form, scale, and layout of urban infrastructure defines the reasonable range of possibilities for design strategies at individual sites within the city. Influencing the core decisions, then, is a way to amplify the adoption of design strategies that can make a difference.

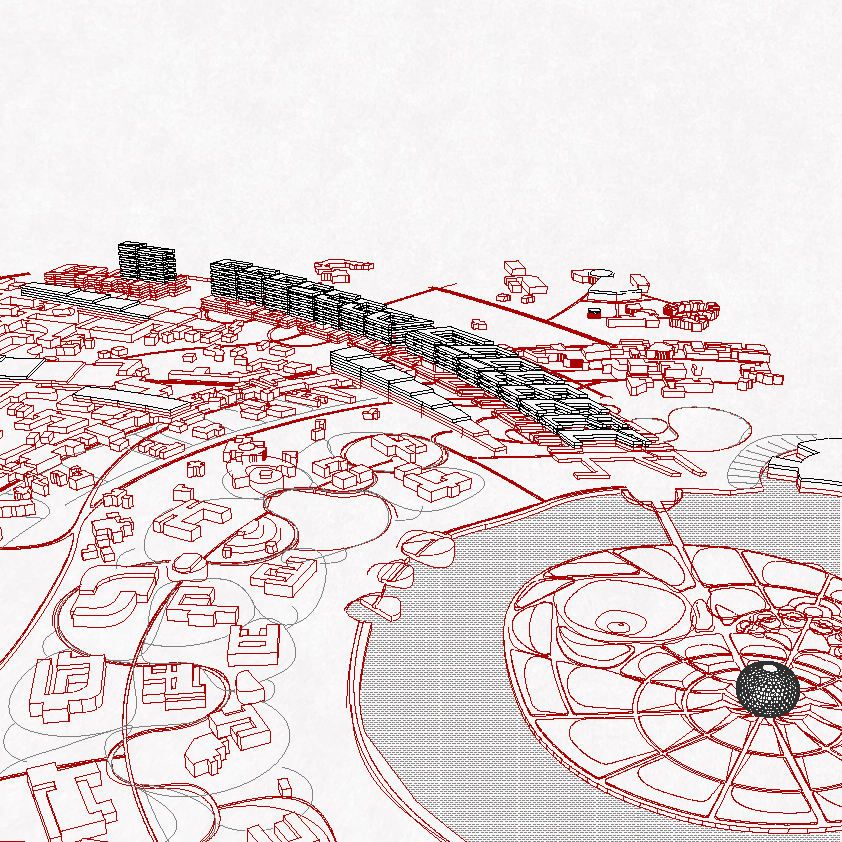

“Line of Goodwill” (Auroville, current) is a high-rise mixed-use project designed for 8,000 inhabitants. It is one of several dense conglomerations envisioned by Roger Anger in a larger city plan for Auroville. Set in the context of a car-free future city in which there is no private ownership of land, the project offers high-density collective living consisting of co-housing clusters with different experimental sharing structures. It rethinks the urban tower (where the human scale is otherwise lost after 8 stories) by introducing several expansive horizontal walkways and public use layers. The gently descending cluster of buildings stretches over 800 m [2,624 ft. 8 in.], resembling a hill that starts at the entrance to the city and culminates at the edge of the lake at the City Centre. The project features integrated water and wastewater systems, renewable energy sources, in-structure urban farming, and smart mobility.

© Anupama Kundoo Architects.

CONCLUSION

Of course, we can achieve big things by adopting small strategies and spreading awareness of their success. But even bigger successes await those of us willing to ask questions and take on problems and paradigms that lie beyond our immediate concerns. How can we expand human potential so that our economic assumption shifts from scarcity to abundance? How can we encourage economic systems that reduce the wasteful consumption of finite natural resources? How do we go about constructing an economy that sees unused time as the greatest waste of all?

Anupama Kundoo is a Professor at the FH Potsdam (Berlin). She is also the principal of Anupama Kundoo Architects. She has lectured and taught internationally, including at the Universidad Camilo José Cela in Madrid, the Parsons New School for Design in New York, the University of Queensland in Australia. She is the author of numerous publications – the most recent being Anupama Kundoo. The Architect’s Studio (2020) - and her work has been featured on several exhibitions, including at the Venice Architecture Biennale (Italy, 2016) and at the Louisiana Museum of Art (Denmark, 2020-21). In 2021, she has been the recipient of the RIBA Charles Jencks Award and of the Auguste Perret Prize for architectural technology. She holds a doctoral degree from the Technical University of Berlin (2008) and an architectural degree from the Sir J. J. College of Architecture, University of Bombay (1989). E-mail: anupama.kundoo@fh-potsdam.de