Professor in Residence, Department of Architecture, GSD, Harvard University, Cambridge MA, USA

To the observer, the building industry strives to develop the most optimized construction materials to build faster, better and cheaper, which has created an expanding pallet of increasingly complex, highly specific product systems. As a result, it is assumed that buildings are comprised of an established collection of parts, selected from a catalogue, and have the consequence of a one-time useful lifespan. This does not suggest that we have abandoned technological development; however, we suspect this approach will stall in its ability to address environmental challenges and create healthy, quality spaces because the sum is not greater than its parts. What if we use and assemble materials in a way that they can serve multiple functions at one time? The 2 in 1 – design strategy is a playful process that assembles materials so one material can incorporate several functions at a time. By finding synergies between well-known, standardized construction elements we can create a positive effect on the quality of building and reduce the carbon footprint.

In response to the world’s climate challenges, the United Nations has set goals to reduce emissions in the Paris Agreement. This is a critical task for the building construction industry, since it represents 38% of total global energy related CO2 emissions.¹ In 2019 the UN Environment Program observed the building industry and as a whole found that the industry is moving away from the Paris Agreement and must rapidly increase its efforts and pace to keep up.

WHY MATERIALS MATTER

The predominant thinking around CO2 reductions has been focused on energy use and efficiency, in particular during the operational period of a building’s life. The building market has focused on creating highly efficient equipment and products, while designers strive to create buildings that require less energy to operate. This effort is just as important today, no doubt; however, as our renewable energy systems and energy use becomes more efficient over time, there is an increased need to focus on the embodied energy of our built environment in order to reduce overall carbon emissions.² This is why materials matter.3 (Fig. 1.)

The International Energy Agency estimates that we need to decrease building CO2 emission by 50% to achieve a net-zero carbon building stock by 2050. The critical question therefore becomes: how can we make aggressive contributions to this effort and still respond to the growing need for buildings? The obvious question should no longer be “if” we build sustainably, but “how” we build the most sustainable buildings possible. This realization means that the building industry must not only advance the craft of designing highly efficient buildings but must also scrutinize the palette from which we build.

WHEN COMPLEXITY LEADS TO SPECIFICITY

As a reaction to this challenge, architects attempt to achieve this goal by either using simple / rural materials, such as clay and wood, or more drastically, by removing components of the building in order to reduce the CO2 footprint of their building.

In contrast, the building industry is trying to develop the most optimized construction materials in order to build more sustainably and in a cost-efficient way. The result is a huge pallet of more and more complex, highly specified multi-component product systems. Many architectural elements end up turning into “machines,” creating a constantly expanding family of assemblies.⁴

The technical solutions presented by the industry can lead to overly specific solutions to singular problems, which can introduce difficulties that come from using additive solutions: one layer after the other is added, while the assembly of the of the individual components into a package becomes more and more difficult, both technically and formally.⁵ The overarching context that we should strive for is lost.

This condition becomes most obvious in the façade because it has developed into a collage of increasingly complex layers, almost impossible to handle by the architect and even more impossible to rate in terms of sustainability. As a result, the role of the architect changes from an innovator to a shopping assistant who helps clients shop out of the catalogue of pre-evaluated and tested materials. As Rem Koolhaas has noted, “The façade is one of the few remaining elements that has not been forgotten by architects - yet most now lack to design the increasingly complex details demanded by contemporary façades. Fabrication and mounting are increasingly farmed out to specialized consultants.” 6

These high-tech composite building elements facilitate, on the one hand, the planning and construction process into prescribed applications and specific functions to accomplish a single goal through a purely quantitative approach. The paradox is born. In pursuit of the single solution, the overall system has become too complex.

MORE THAN JUST THE SUM OF ITS PARTS

The issue of the above-mentioned approach is that it treats sustainability as a purely quantitative problem and tries to solve it by calculation and reduction in the sense of applying technological solutions to solve a problem. What happens if we reduce and simplify our material use as much as possible and still do not hit the CO2 target? What happens if adding technology cannot fix our problems?

In his ten books about architecture, Vitruvius describes the development of the first dwellings when people first discovered materials (stems, leaves etc.) and tried to figure out what they could do with them – roof/wall etc. In other words, there was already a curiosity about optimizing the use of simple materials. Since then, building construction has been in a process of continuous optimization.7

This optimization has led to the creation of a highly advanced, established vocabulary of building components, each with a prescribed function, application, and composition. On the one hand, the process to assemble this vocabulary can be quite prescriptive and the decision making a binary process; it either is or is not designed for an application.

Could it be valid that our buildings are comprised of situations in which this vocabulary actually takes on a plural quality where the condition or system has two or more states or functions? A direct interpretation of this idea might be that the structural floor becomes the finish floor and no other floor product is required. However, if we truly expel our binary assumptions, we might not only question beyond the mere function of a material, but also question whether a material arrangement can serve two purposes, performing a range of tasks beyond those typically assumed. (Figs. 2, 3.)

We should not forget through all of this optimization that sustainability has a direct impact on people’s lives. It is clear that our buildings need to achieve a carbon neutral status, but we also know that buildings are a human invention, for human use, and should be human-centered. Can we not address climate change and implement strategies to improve health and education, reduce inequality, and generate economic growth through our material choices? 8

Sustainability is more than numbers. Is there a way beyond pure optimization and specification; a more playful approach to sustainability? For sure, we should not go back to the past and ignore all of the development in the material sector that has been developed up to this point. But doesn’t it sound exciting, just to simply look at what we can find on the market and figure out what other things we can do with these standard products? What if we use and assemble materials in a way that they can serve multiple functions and by doing so react to everyday, seasonal, and generational changes? (Fig. 4.)

2 in 1 – DESIGN STRATEGY

The following design approach is the result of continuous research through design in the offices of Behnisch Architekten in Stuttgart, Munich, Boston and Los Angeles. With this article we would like to share our experiences on our way to an integrated, adaptive approach that provides for a sustainable design methodology which questions existing building methods and tries to find new approaches to carbon neutrality beyond pure optimization and reduction. In this process the selection and assembly of material plays a major role.

The 2 in 1 – Design Strategy tries to provide an answer to the challenge of sustainable building by using and assembling materials in a way that one material can incorporate several functions at a time. The core idea of this approach lies in finding synergies between well-known, standardized construction elements with the aim of creating a positive effect on quality as well as reducing the carbon footprint of the building.

Looking at the composition of a modern floor system, for example, a floor today is much more than a pure constructive element. A floor is an assemblage which, apart from its structural function, provides heating, cooling, air conditioning, electricity, acoustic treatment and often a number of other functions. To fulfil all of these demands it consists of an extensive package of specialized elements optimized for their specific task – raised floors, electrical installations, constructive slabs, air ducts, and suspended ceilings, to name just a few. These standardized building elements facilitate, on the one hand, the planning and construction process. On the other hand, however, their specificity restricts their flexibility in use and re-use.

The least durable material dictates the life cycle of the whole component and is often specified to only one function, which does not provide any flexibility in use or transformation. Worst case, this “floor machine” adds to the CO2 footprint in multiple ways through its additive assemblage of components, therefore requiring additional space. This consequently increases the amount of heated building volume needed to achieve a certain clear height within the building’s floor levels. This, as a result, increases one of the most carbon intense elements in the building – the primary construction. Therefore, it could be argued that the assemblage of individual, optimized carbon neutral components can actually lead to a non-sustainable design.

Considering that the carbon footprint of a building is primarily dependent upon the heated volume provided per person as well as the material used to build this heated volume 9 several optimizations become apparent: One option could be the further optimization of each single element. This, however, promises to become a time-consuming and non-cost-effective process. Another approach could be the simple elimination of several layers, causing perhaps a functional as well as qualitative reduction. What often happens in practice is a compromise solution: the clear heights in the so-called functional rooms of the building – corridors, toilets, storage – are lowered in order to keep more clear height in other spaces while maintaining a reasonable story height. But this could have a significant effect on the flexibility and lifecycle of the building by creating predetermined, inflexible spaces. The decision turns out to be a dilemma.

It is at this point the “2 in 1 - Design Strategy” enters the game. If you throw all your knowledge about construction “overboard” and try to look at the assemblage of the above mentioned “floor machine” in an open, almost childlike way, then what would one see? A layer cake consisting of mass and voids. A porous object which invites the question: how can these unused, empty spaces be effectively used? What if we could directly use the existing voids of a constructive floor element as a channel system and therefore save the carbon emission of the duct work, decreasing the heated building volume as well as its primary construction. All without creating any compromises in quality. (Fig. 5.)

A striking example for this synergy-based design approach is the construction of the Conference Hall for the World Intellectual Property Organisation (WIPO) in Geneva, Switzerland, by Behnisch Architekten (2014). In a technically intense building typology such as a conference hall, ventilation plays a major role through the high demand on the air exchange rate as well as the ability of the system to react to different energy demands in a minimum amount of time. The resulting dimensions for the ventilation system have an important effect on the constructed heated volume and thus the building’s overall carbon footprint.

Due to its positioning on an existing underground parking garage, the WIPO conference hall is designed as a lightweight wooden structure made of prefabricated beams and slabs, joined with steel plates, optimized in its dimensions.10 In this context the efficiency of the construction and the weight of the building played a major role. The structure offered the possibility to use the already available voids of the construction as air ducts, thus providing every seat in the hall with direct ventilation. Through this synergy, the volume and construction as well as the energy load of the building could be reduced. (Figs. 6-8.)

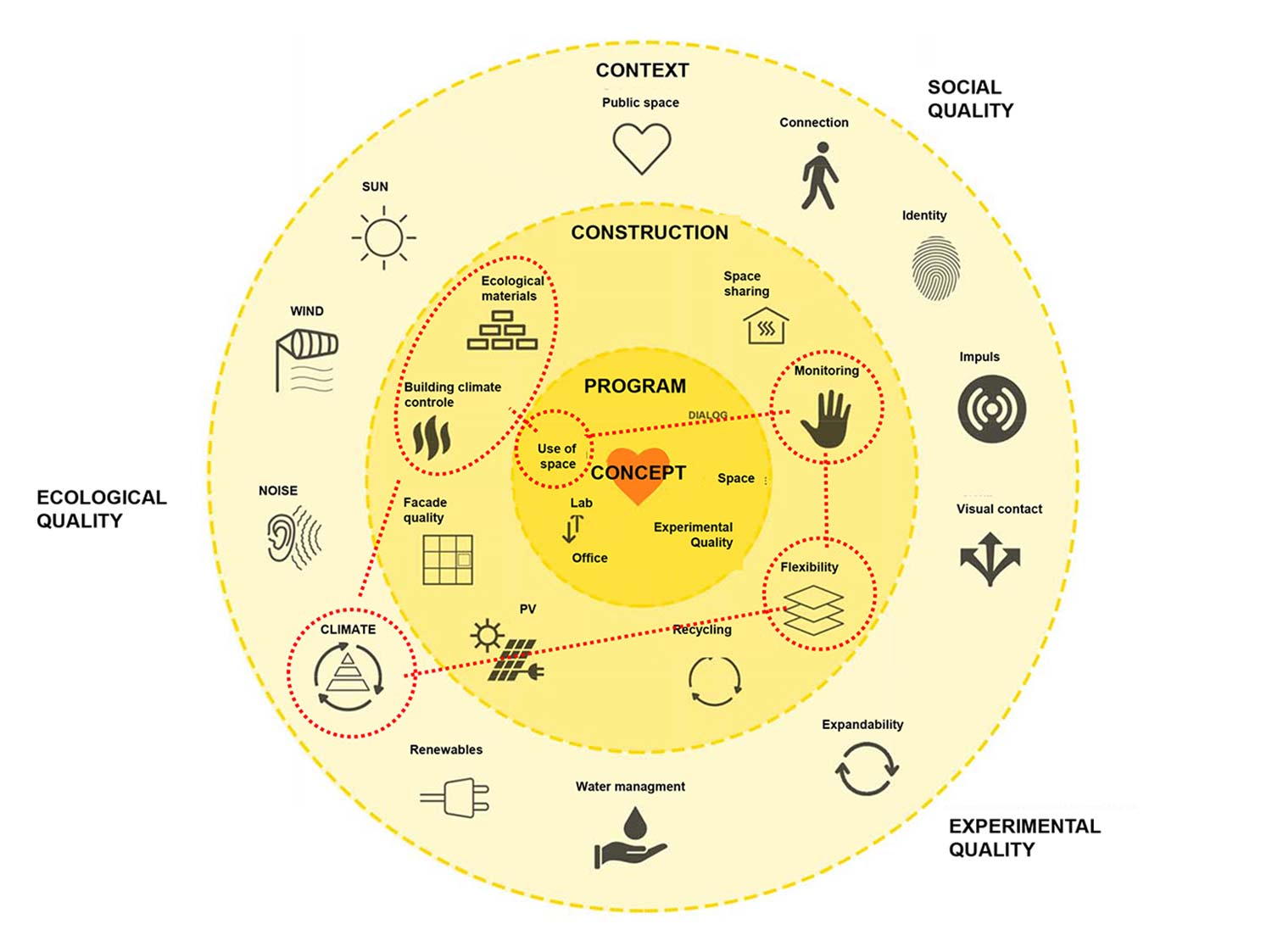

Furthermore, we, at Behnisch Architekten, developed this design approach in a project for the Smart Living Lab (SLL) situated on the Blue Factory Campus in Fribourg, Switzerland (2019). The Smart Living Lab brings together the combined expertise of the Swiss Federal Institute of Technology Lausanne (EPFL), the School of Engineering and Architecture of Fribourg (HEIA-FR), and the University of Fribourg (UNIFR) in research areas such as construction technologies, well-being and behaviors, interactions and design processes, and energy systems. This is a client working on the future of sustainable construction with high demands on the performance and the carbon footprint of its building. As a result, the task was to create a building that can be very flexible in use due to the ever-changing research topics and groups of the institutions. Even a scenario with a residential use is to be considered. This challenging task turned out to be the perfect testing ground for the 2 in 1 methodology.

Based on these demands, the main structure consists of European beech timber columns and prefabricated wooden box slabs which provide a flexible floor plan with a grid of 6 by 6 m [19 ft. 2 in. by 19 ft. 2 in.]. The wooden box slabs, which in section already look like a perfect channel system, were tested to incorporate more than one function. The integration of the air distribution allows for the elimination of additional metal air ducts and therefore provides maximum flexibility in the use of the building. This had an impact on the orientation of the slabs and the assembly of the primary structure of the building which required that an interdisciplinary team be on board from the very start of the project. (Fig. 9.)

But even if it is possible to find as many synergies as possible, new construction always emits CO2. In order to achieve carbon neutrality, buildings not only need to reduce their CO2 consumption, they need to gain CO2 credits through the generation of renewable energy. This is a paradox. For example, simply adding PhotoVoltaic (PV)-cells to a project increases the CO2 consumption, considering that the fabrication of a PV Panel is a CO2-intense process. Finding the right balance here proves to be challenging. If greenhouse gas emissions are the target values, then a certain amount of PV Panels are needed. Providing additional surfaces for PV elements means increasing the building volume, which defeats the purpose. This raises the amount of total energy demand and CO2 emissions considerably. In other words, it is not only the PV cells that count here, but also the additional roof surfaces and sub-constructions needed for mounting the PV panels.

Out of this dilemma the concept of combining two things in one emerges – Why not use the PV panels as sun shading devices? They can provide an optimized brise-soleil which shades the façade while simultaneously generating renewable energy, creating an integrated renewable energy system in a CO2 efficient way – shading to reduce overheating while also producing energy. The façade is therefore actively contributing to the overall energy performance of the building while taking care of the elemental task of shading. In the vertical direction the elements provide both shading and energy, whereas in the horizontal direction the elements provide shading, generate energy and also function as light-shelves, allowing daylight to penetrate deep into the building, reducing the overall need for energy consuming artificial lighting. (Fig. 10.)

Elements are sized and oriented to ensure optimized production and at the same time providing shading in summer. Each elevation responds to the sun exposure and building envelope. Elevations with dominantly east and west sun exposure incorporate deep vertical fins, while the east façades have strong horizontal fins. In the north façade, vertical fins are reduced to a minimum. Extensive solar shading studies were undertaken to optimize the layout. It was very important that the fins are not only custom tailored towards their solar exposure but are also able to maintain unobstructed views to the surroundings. The fins consist of a PV element mounted on a wooden frame – in other words, a large energy harvesting surface! 11 (Fig. 11.)

In a recent project for a design competition in Hamburg, Germany (2020), we developed this approach even further. Hamburg, as one may well know, has a special climate – it is quite windy. An additional membrane, which serves as a solar shading device in summer also acts as a wind buffer and additional “insulation” layer in winter. Efficient and agile in its use, the system transforms the appearance by adapting to the climate and the needs of its inhabitants. (Fig. 12.)

A methodology such as this has an impact on the entire design process. Sustainability needs to become an integral part of the process from the very beginning of the project. In contrast to traditional design processes where the architect first designs the building and then invites the engineers to “make things work”, this methodology requires an integrated design approach from day one – a collaborative, interdisciplinary team working together from the very beginning of the project. Openness and flexibility in design thinking is a requirement. Preconceived notions about what an element normally is used for should be set aside in favor of open, creative design thinking. Only through this approach is it possible to discover, as described above, in an intelligent yet perhaps “childlike” way, the unexplored possibilities of materials.

This 2 in 1 design strategy doesn’t claim to be the only or most efficient approach to sustainable design. But it tries to give an alternative answer to the social and environmental challenges of our time through the creative application of good and sustainable material.

SUMMARY

Sustainability needs to become an integral part of the design process. This has an impact on the entire building process. The rules of the project phases which are predefined in most countries, like the HOAI in Germany, where the architect first designs the building and then an increasing number of technical consultants join over the phases does not suit this process.

Building simple is a complex thing. The resulting buildings should be agile living objects which are able to adapt to the climate, their surroundings and not least to the needs of their inhabitants by the creative application of good and sustainable material. This design methodology can provide an answer to the technical, financial and social environmental challenges of our time.

We should start to understand our buildings as toolboxes, as a part of a bigger lifecycle, constructed with elements users can flexibly use and exchange. The goal is not to create inflexible, non-reusable “one-off objects”. This should not take away our duty to design structures that are vital parts of the urban fabric as well as optimized spaces for its users. Sustainability should not act as a hindrance to architectural design but rather as a catalyst for reinterpretation and adaptation, so that by simply asking the question “what is this and for what can I use this?” new opportunities emerge.

United Nations Environment Programme, “2020 Global Status Report for Buildings and Construction: Towards a Zero-emission, Efficient and Resilient Buildings and Construction Sector,” Nairobi: 2020.

“Why the Building Sector?,” Architecture 2030 website, 2021 - https://architecture2030.org/ why-the-building-sector/, accessed March 9, 2021.

Forestry Innovation Investment (2017): Embodied Carbon of Buildings and Infrastructure -

https://www.naturallywood.com/resource/embodied-carbon-of-buildings-and-..., accessed November 10, 2021.

Walter Belz, Zusammenhänge (Cologne, Ger.: Rudolf Müller, 1999), 13.

See Rem Koolhaas, Elements of Architecture (Cologne, Ger.: Taschen, 2018).

Ibid., 47.

Marcus Vitruvius Pollio, Zehn Bücher über Architektur (Darmstadt, Ger.: Wissenschaftliche Buchgesellschaft, 1991), book Two, chapter One, 79; first English ed., 1771-91; first Italian ed.: Venice, It., 1511; or. Latin ed., De architectura (On Architecture), first cent. BCE.

United Nations Department of Economic and Social Affairs, “The 17 Goals,” United Nations, 2021 - https://sdgs.un.org/, accessed May 9, 2021.

Thomas Jusselme, Research at the Service of Building Design, in Exploring, Research Driven Building Design, ed. Marilyne Andersen, Emmanuel Rey (Zurich: Park Books, 2019).

Stefan Behnisch, “Why Wood?”, Behnisch Architekten website - https://behnisch.com/updates/essays/why-wood, accessed June 9, 2021.

Aulikki Sonntag, “Research-Driven Building Design to Achieve 2050 Objectives. Case Study of Smart Living Lab Building (Fribourg),” Women Shaping Our World, 2019 -

http://igsmag.com/igs-autumn-2019-issue/, accessed June 9, 2021.

Figures 1, 2, 4-6, 9, 10, 12: images by © Behnisch Architekten.

Figure 3: image by © Behnisch Architekten, photo by Brad Feinknopf

Figures 7 and 8: images by © Behnisch Architekten, photo by David Matthiessen

Figure 11: image by © Behnisch Architekten, visualization by MOKA Studio

Angie Müller-Puch, Dipl.-Ing. Arch, is a Director and Project Manager at Behnisch Architekten in Stuttgart, Germany. She has gained extensive experience in design competitions and has worked on award winning projects at national and international level, including the Lycée Franco-Allemand (German French School) in Paris; development of the school district in Bernhausen (Germany); and the Smart Living Lab, in Fribourg, (Switzerland). She has been a lecturer and guest critic at the RWTH Aachen University (Germany), the University of Stuttgart (Germany) and the HEIA Fribourg, (Switzerland). Since 2021, she is a member of the Strategy Group for Sustainable Design of the Chamber of Architects of Baden-Württemberg (Germany).

Email: am@behnisch.com

Erik Hegre, M.Arch., AIA, is a Director and Project Manager at Behnisch Architekten in Boston. He has worked on a number of award-winning projects and has extensive experience guiding multi-disciplinary teams through the design for highly specialized space building types such as research, imaging, specialized laboratories, and educational facilities. Completed projects include the Harvard Science and Engineering Complex in Boston, the Robert L. Bogomolny Library at the University of Baltimore, Baltimore MD (USA), and the Karl Miller Center at Portland State University, Portland OR (USA). He is an instructor at the Yestermorrow Design Build School since 2003 and his research has been published by the Association of Computer Aided Design in Architecture - ACADIA (2009 and 2010).

Email: eh@behnisch.com

Michael Innerarity, M.Arch, is a Director and Project Manager at Behnisch Architekten in Stuttgart, Germany. He has worked on a number of award-winning competitions and projects and has extensive experience in education, laboratory and health care design. Completed national and international projects include the Harvard Allston Science Complex in Boston, the Information and Resource Center for the Ukrainian Catholic University in Lviv (Ukraine), the Agora Cancer Research Center in Lausanne (Switzerland) and the expansion of the National Center for Tumor Diseases (NCT) in Heidelberg (Germany).

Email: mi@behnisch.com